When it comes to construction projects, choosing the right materials is crucial for the success and durability of the structure. One material that is commonly used in the construction industry is formply. However, with so many options available in the market, selecting the best formply for your building needs can be a daunting task. In this article, we will provide you with some helpful tips to make the selection process easier and ensure that you choose the most suitable formply for your project.

Understanding the Basics of Formply

Before delving into the tips for selecting the right formply, let’s start by understanding what exactly formply is.

What is Formply?

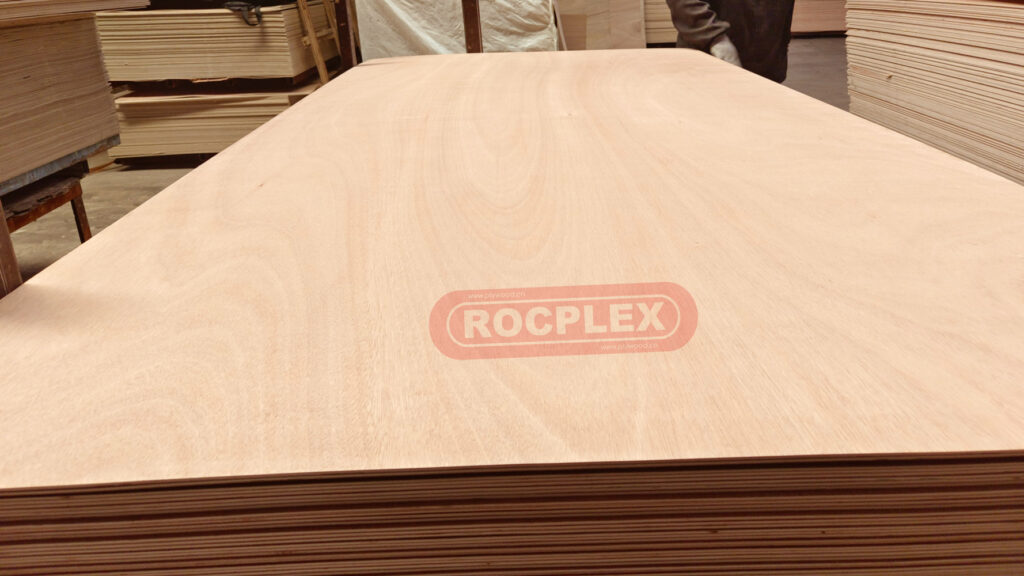

Formply, short for “forming plywood,” is a type of plywood that is specifically designed for use in concrete formwork. It is used as a mold or framework to hold the poured concrete in place until it sets and hardens. With its smooth surface and high-quality construction, formply provides a sturdy and reliable formwork solution for various construction projects.

Key Features of Formply

Formply stands out due to its unique features, which make it ideal for use in demanding construction applications:

- High strength and durability

- Moisture resistance

- Excellent dimensional stability

- Resistance to warping and splitting

Formply is manufactured using high-quality hardwood veneers that are bonded with waterproof glue, making it resistant to moisture and ensuring its longevity in wet concrete environments. The smooth surface of formply allows for easy release of the concrete after it has set, reducing the need for additional finishing work.

Additionally, formply undergoes a special treatment process that enhances its dimensional stability, preventing it from expanding or contracting excessively with changes in humidity. This feature is crucial in maintaining the integrity of the concrete formwork and ensuring precise concrete shapes and finishes.

Now that we have a basic understanding of formply, let’s explore some important factors to consider when selecting the right formply for your project.

Factors to Consider When Choosing Formply

Material Quality

The quality of the formply is a crucial factor to consider. Opt for formply that is made from high-quality, durable materials, ensuring that it can withstand the rigors of construction. Look for formply that meets relevant industry standards and certifications.

High-quality formply is typically constructed from hardwood veneers that are bonded together with waterproof glue. This construction ensures the formply’s strength and durability, making it ideal for use in concrete formwork applications. Additionally, premium formply is often subjected to rigorous quality control measures to guarantee its performance and longevity on construction sites.

Size and Thickness

The size and thickness of the formply will depend on the specific requirements of your project. Consider factors such as the size of the structure, load-bearing capacity, and the desired finish of the concrete surface. Thicker formply may be preferable for larger structures or where higher concrete pressures are anticipated.

When selecting the size and thickness of formply for your project, it is essential to consult with structural engineers or formwork specialists. They can provide valuable insights into the optimal dimensions based on the structural design and concrete pouring requirements. Thicker formply panels offer increased strength and stability, reducing the risk of deflection or deformation during the concrete pouring process.

Weather Resistance

Construction sites are often exposed to various weather conditions. Therefore, it is important to choose formply that is weather-resistant and can withstand exposure to moisture, sunlight, and other environmental elements. Look for formply that has been treated with water-resistant coatings or chemicals. Learn more about resistant at https://hopkinsdiabetesinfo.org/what-is-resistant-starch/

In addition to water-resistant treatments, some formply manufacturers offer specialized coatings that provide enhanced protection against UV radiation and extreme temperatures. These advanced weather-resistant features help prolong the lifespan of the formply and maintain its structural integrity in challenging outdoor environments. Investing in weather-resistant formply ensures that your formwork remains robust and reliable, even in adverse weather conditions.

The Role of Formply in Construction

Formply, a type of plywood specifically designed for formwork in construction projects, plays a crucial role in ensuring the structural integrity and quality of concrete structures. Its smooth surface and high durability make it an essential material for achieving a flawless concrete finish.

One of the key benefits of using formply is its ability to provide a consistent and even surface for concrete pouring. This results in a uniform finish that meets the highest standards of quality and aesthetics. Additionally, formply’s precise formwork capabilities enable builders to create complex shapes and structures with accuracy and efficiency.

Benefits of Using Formply in Building

Using formply in construction offers several benefits:

- Provides a smooth, even concrete finish

- Ensures precise and accurate formwork

- Offers superior strength and stability

- Reduces the risk of concrete leakage

Moreover, formply’s superior strength and stability make it a reliable choice for supporting heavy concrete loads during the construction process. This durability not only enhances the safety of the construction site but also contributes to the long-term resilience of the completed structure.

Common Uses of Formply

Formply is widely used in various construction projects, including:

- Residential buildings

- Commercial structures

- Bridge construction

- Infrastructure projects

Its versatility and adaptability make formply a versatile material suitable for a wide range of applications in the construction industry. Whether it’s forming foundations for high-rise buildings or creating intricate molds for architectural features, formply continues to be a preferred choice among builders and contractors for its reliability and performance.

Tips for Selecting the Right Formply

Assessing Your Building Needs

Before making a final decision, carefully assess your specific building needs. Consider factors such as load requirements, duration of the project, and the desired quality of the concrete finish. This will help you determine the most suitable formply for your construction needs.

It is essential to understand the importance of selecting the right formply for your construction project. The formply you choose will have a significant impact on the structural integrity and overall quality of the concrete finish. Take into account the environmental conditions of the construction site, such as exposure to moisture or extreme temperatures, as these factors can influence the performance of the formply over time. Click here to find more about integrity.

Comparing Different Brands

Research and compare different formply brands in the market. Look for reputable manufacturers that have a track record of producing high-quality formply. Read customer reviews and seek recommendations from industry professionals to make an informed decision.

When comparing different formply brands, pay attention to the specific features and specifications of each product. Consider factors such as the type of wood used, the number of layers, and the quality of the adhesive bonding. These details can help you determine which formply is best suited for your project requirements and budget constraints.

Seeking Professional Advice

If you are unsure about which formply to choose, seek advice from construction professionals or structural engineers. They can provide valuable insights and recommend the most suitable formply based on your specific project requirements.

Professional advice can help you avoid costly mistakes and ensure that the formply you select meets the necessary standards and regulations. Consulting with experts in the field will give you peace of mind knowing that you have made an informed decision that aligns with the best practices in the construction industry.

Proper Maintenance and Care for Formply

Formply, a type of plywood specially designed for concrete formwork, requires proper maintenance and care to ensure its longevity and performance on construction sites. In addition to cleaning and storage, there are other essential aspects to consider when handling formply.

Cleaning and Storage

Proper maintenance and care can significantly extend the lifespan of your formply. Clean the formply after each use, removing any concrete residue to prevent buildup and damage. Store the formply in a dry, well-ventilated area to avoid moisture absorption and warping. Additionally, consider using protective coatings or sealants to enhance the formply’s resistance to moisture and prolong its lifespan.

Inspection and Maintenance

Regular inspection of formply is crucial to identify any potential issues early on. Look for signs of wear, such as surface damage or delamination, which can compromise the structural integrity of the formply. Address any issues promptly through repairs or replacements to maintain the quality and safety of your formwork system.

Lifespan and Replacement

While formply is known for its durability, it is essential to monitor its condition over time. Regularly inspect the formply for signs of wear, delamination, or damage. Replace any damaged or deteriorated formply to ensure the safety and quality of your construction project. Properly maintained formply can last for multiple uses, providing cost-effectiveness and reliability for your formwork needs.

By considering these tips and factors, you can make an informed decision when selecting the best formply for your building needs. Remember, choosing the right formply is an investment in the success and longevity of your construction project.

Read about F14 Grade Plywood at: F14 Grade Plywood